Profile

About Siltech

As an Innovation company Siltech has built a reputation of creating novel ingredients to meet the challenges faced by formulators as they seek to satisfy modern consumer desires. Siltech offers solutions for improving numerous functional attributes such as wetting, conditioning, emulsification, film formation, gloss, and dispersion in cosmetic formulations and specializes in customization to meet formulator needs. Sustainability pervades Siltech’s tactical and strategic decisions and our newest developments include increasing renewable product content and a biobased formulation focus. Siltech remains committed to leading the development of unique ingredients to benefit the ever-evolving personal care industry.

Siltech operates two manufacturing plants in Canada. Both sites have the capability of scaling up products from the lab through to full 20,000 kg batches.

Siltech New Developments

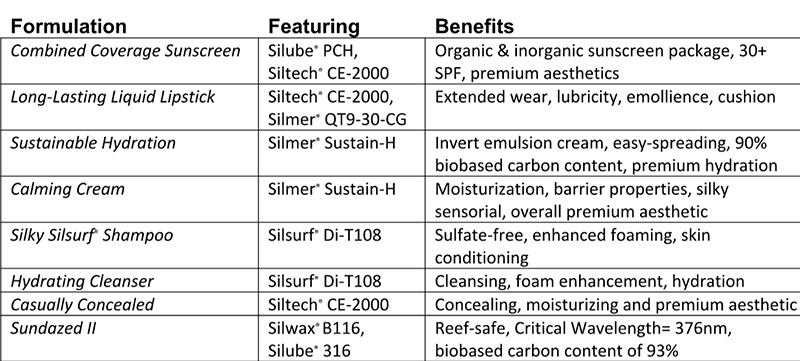

Siltech launched numerous innovative products and formulations to highlight the benefits of those products in 2021. Siltech continues to promote sustainability in cosmetics and our newest offerings and formulations feature maximized sustainability.

Sustainability/ Silmer Sustain-H

Siltech is excited to continue helping formulators in their pursuit of product sustainability. Our newest product offerings focus on maximising biobased carbon content and our chemists continue to design formulations that promote sustainability. Our formulas containing Siltech products generally have verified biobased carbon content above 90%! Our product Silmer Sustain-H is an elastomer gel in a renewable hemisqualane carrier. It provides premium performance and has a biobased carbon content above 90% and is featured in our example formulation Sustainable Hydration, which itself has an overall biobased carbon content rating of more than 90% as verified by testing outlined in ASTM D6866. The addition of the Silmer Sustain-H in the formulation contributes to an exceptional sensorial, emolliency and ultra-hydration. This product is also featured in our formulation Calming Cream. The INCI name for Silmer Sustain-H is C13-15 Alkane (and) Dimethicone/ VinylDimethicone Crosspolymer.

Silwax B116

Silicone waxes provide a variety of benefits in personal care applications, including improved spreadability, enhanced oil solubility and a potential SPF boost in sunscreens. Silwax B116 is a clear, low viscosity alkyl dimethicone offering that is easily incorporated into formulations to provide numerous benefits. Lab studies have shown that inclusion of just 1% Silwax B116 into sunscreen formulations noticeably reduces white-cast rub-out times. This product is featured in our Sundazed II sunscreen formulation, which itself sports a in-vitro SPF of 16, with a critical wavelength at 376nm, and a 93% biobased carbon content rating. Silwax B116 has an INCI name of Cetyl Dimethicone.

Siltech CE-2000

Siltech is pleased that recently conducted lab studies prove that in-vitro SPF values can be boosted by our long-standing citrate ester offering, Siltech CE-2000. We compared the performance of Siltech CE-2000 to Alkyl Benzoate, a common sunscreen active dispersant, and found a 20%+ increase in UVA values when using Siltech CE-2000! Siltech CE-2000 is a non-comodogenic citrate ester that provides superior pigment dispersion compared to common dispersants. Color cosmetic chemists are likely familiar with using Octyldodecanol, Castor Oil and Polyglyceryl-3 Diisostearate for pigment dispersion. Siltech CE-2000 outperforms them all and is additionally a good emollient, while offering cushion in lipsticks. This oil soluble product with unique wetting properties is highlighted in our formulations Long-Lasting Lipstick, Agreeable Resistance Lipstick, Under Cover Sunscreen, Combined Coverage Sunscreen and Casually Concealed Foundation. The INCI for Siltech CE-2000 is Trioctyldodecyl Citrate.

Silube PCH

Silube PCH is a versatile nonionic invert (W/O) emulsifier that imparts stability across a wide range of applications, most notably creams and sunscreens. Resulting emulsions exhibit long-term stability and offer superior hydration versus regular (O/W) counterparts. Silube PCH excels at compatibilizing UV actives to maximize SPF performance. The INCI name is Polyglyceryl-4 Isostearate (and) Cetyl PEG/PPG 10/1 Dimethicone (and) Hexyl Laurate. It is featured in our formulations Under Cover Sunscreen and Combined Coverage Sunscreen.

Formulations