Velox develops and manufactures industrial-grade digital decoration solutions for the packaging industry. Its proprietary direct-to shape inkjet technology, based on uniquely formulated inks and dedicated deposition architecture, introduces an entirely new approach to digital printing that is poised to disrupt the packaging decoration market.

Velox’s commercial solution, Velox IDS 250, is the world’s only industrial-grade digital decorator for mass production of cylindrical containers. It delivers superior decoration quality and enhancements that outstrip the benefits of analog printing solutions, while allowing a more efficient and flexible production process and a low total cost of ownership.

Next generation packaging

Velox’s breakthrough decoration technology transforms cosmetics and personal care products packaging such as tubes and cans into a powerful consumer engagement platform, delivering strategic advantages in three key areas:

Unprecedented Brand Visibility

It’s about far more than vibrant colours, photorealistic images and ultra-fine details. Velox’s technology also provides the ability to print directly on the cap and make it part of the overall design, to print 360° around the container, with no seam or overlap, and to easily apply embellishments such as digital gloss or tactile affects in the same printing process. The result: packaging decoration that fully delivers brand messages and makes products truly stand out on the shelf.

Brand shelf visibility is significantly enhanced through unique digital decoration features

Major Business Impact

Imagine ultra-short lead-time, quantity-independent economics and inherent mass customisation, all applicable for the entire product line, and not just for special editions. Proactive wide-scale decoration strategies can now be executed, while maintaining fast responsiveness to meet market conditions.

Once Velox high-speed direct-to-shape digital decoration technology is deployed, packaging manufacturers can support any need from the brand-owners and enable them to meet their strategic objectives.

Unlimited mass customization and micro-segmentation as ongoing business strategies

Significantly Improved Sustainability

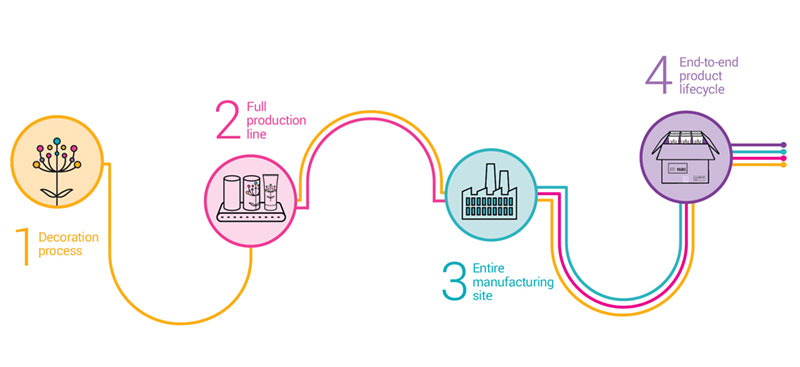

Velox’s digital decoration technology delivers major sustainability benefits across every step of production and throughout the entire supply chain. This includes the reduction of substrate and chemical waste by eliminating setup waste and the need for plates, screens, blankets, chemicals and spot inks.

Velox’s mass production digital technology increases existing production line capacity and efficiency and reduces energy consumption, storage, chemical handling units, and downtime. The inherent flexibility of digital technology enables a shift to on-demand production, reducing inventory and eliminating overproduction. This also simplifies the supply chain because it reduces transportation and stock logistics, improves planning, shortens time-to-market, and drastically reduces wastage of final goods.

Visit us at Cosmopack Asia Hong Kong, November 12-14, Hall 9, Stand 9-C20.