MJ Deschamps takes a look at technology that is taking a leap from outer space to the consumer’s face

In today’s beauty obsessed society, sometimes no price is too high for an anti-ageing product that is out of this world: something certain cosmetics companies have taken to heart quite literally.

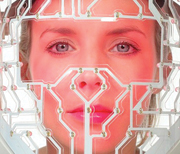

UK cosmetics company Turn Back Time has recently followed in the footsteps of other cosmetics and beauty companies, looking to aerospace technology to create innovative, anti-ageing solutions. In November 2010 the company introduced face masks inspired by NASA technology, which use different light wavelengths to produce anti-ageing and anti-acne effects.

“Space technology inspired our facelift mask when we came across studies showing the effect of NASA LED [light emitting diodes] irradiation on wound healing,” says Turn Back Time’s md, Andrew Stefanczyk.

And NASA scientists have indeed proved that LED light therapy promotes human tissue growth: the technology’s energy enhances cellular metabolism, accelerates the repair and replenishment of damaged skin cells and stimulates the production of collagen, the foundation of a healthy, smooth skin.

“It became apparent that this technology could be successfully utilised in the beauty industry,” says Stefanczyk. He reports that demand for the masks has been huge since their release on the market last autumn. Turn Back Time developed two different masks, each using a different LED light frequency. “The red LED works well as a non-surgical facelift by stimulating the collagen in lower skin layers, and the blue LED helps to clear acne and spots by killing the bacteria that causes the condition,” says Stefanczyk.

Turn Back Time is far from being the first company to use LED lasers and other technologies originally developed for the space industry to make cosmetics products.

One of the more famous commercial space spin-off innovations is Crème de la Mer, created by aerospace scientist Max Huber who was severely burned by chemicals while performing an experiment. When he could find nothing available to soothe his skin, he came up with his own formula to do the trick, which eventually became a luxury skin care product now owned by Estée Lauder and boasts a whole range of line extensions. And Crème de la Mer is not the only space-based development used by the company. Lauder has long used digital image analysers and software based on NASA lunar research to evaluate cosmetic products. This is because digital image processing brings out subtleties that would otherwise be undetectable, allowing better determination of a product’s effectiveness.

Skin care isn’t just important to those on Earth though – it is also a big concern to astronauts. Since the harsh space environment can dry out skin, astronauts need special skin products. In 2006, a project called the Skin Care Experiment was conducted on the International Space Station, investigating the effects of microgravity on human skin. Astronauts and cosmonauts living on the International Space Station are constantly exposed to conditions that stress their skin. For example, the constant draft from the station’s ventilation system dries the skin, making it more susceptible to scratches and irritation, and it was also observed that the skin becomes thinner in microgravity conditions. On Earth we experience a phenomenon that shows similar effects on human skin, but we call it ageing. These observations lead to the hypothesis that skin in space could be a suitable model for skin ageing on Earth. Clearly the research potential here is significant.

Meanwhile L’Oréal has undertaken interesting cosmetics research derived from space technology by using European Space Agency (ESA) pollution maps along with ultraviolet radiation data to investigate the possibility of producing skin care products customised for local conditions.

Mexico City, one of the most polluted cities in the world, was used as the backdrop for the experiment to study the effects of ozone and nitric oxide on the skin. People in a highly polluted district of the city were compared to subjects living in a less exposed urban area 75km away.

Turn Back Time masks use red and blue LED irradiation – which NASA scientists have found to promote human tissue growth – to stimulate collagen and kill acne-causing bacteria

The cosmetic consequences of pollution turned out to be real and, depending on the pollution levels, skin and hair smoothness and brightness change. Also oxidation compromises the skin’s natural defences and could enhance irritation and allergic reactions.

Differences were sufficiently pronounced between people living less than a hundred kilometres apart that researchers grew interested in acquiring more precise information on regional air pollution levels.

Space technology can also be extended to cosmetics packaging and storage. In 2004, French manufacturer of specialist container solutions Thermagen developed an innovative cooling storage solution for the cosmetics industry, using a packaging concept adapted from a technique developed by ESA to propel its Ariane rocket into space. The cooling technology used in the rocket engines is entirely self-sufficient and doesn’t rely on any other energy source to operate.

According to Thermagen, the technology can cool a product from 22°C to 2°C in less than two minutes.

Thermagen technology was used by Cosnessens in 2004 for Ice Source. The brand combined the ultra-fast cooling effect with a particular combination of skin care ingredients, including a rare extract of Arctic raspberry, to provide an immediate lifting effect when applied to the skin.

A more recent technology transfer in the realm of cosmetics packaging is helping cosmetics companies to protect themselves against counterfeiters. Thanks to a new laser technology developed for space, a Belgian start-up company called Trackinside is now able to inscribe numbers in glass without cracking, heating or leaving any external marks on the glass. “It’s the only technology that can mark glass without damaging it,” says Jean Michel Mestrez, Trackinside’s md. The low-impact laser can be used to inscribe serial numbers inside rather than on the surface of the glass used in perfume vials, for example. This technology made its way to the market through the ESA’s Technology Transfer Programme Office (TTPO). The TTPO’s main mission is to facilitate the use of space technology and space systems for non-space applications and to demonstrate the benefit of the European space programme to European citizens.

“It’s very important to commercialise space technology as billions of dollars are spent in research that has a very narrow application,” says Stefanczyk. “A lot of the money invested comes from people paying their taxes. We therefore think it is fair that everybody should be able to benefit from the research.”