Alvott produce moisturising body creams and other cosmetic products which are formulated with all natural ingredients such as shea butter, cocoa butter and coconut oil. The unrefined fats in these ingredients have a wide range of different uses such as lip balm, sunscreens, hair masks, body creams and even as a healthy alternative to cooking fats, making these products incredibly versatile.

Alvott, a family-owned business, was founded when it became apparent that very few people knew how to process these natural ingredients, especially Shea butter in the old- fashioned, traditional way to retain the essential qualities of the ingredient. Having experience and knowledge of the traditional method and utilising fair trade sources in Ghana to obtain the ingredients, Alvott is able to source and produce excellent unrefined raw material for use in their cosmetic products ensuring that these products are of the highest quality.

Due to the high quality of the ingredients used in the products it was essential to reduce wastage as much as possible while keeping the quality of the products consistent between batches so that each customer would receive the highest quality products – that’s where Silverson Machines came in. Alvott first got in touch with Silverson Machines in April 2020 when we received an enquiry from Chief of Operations and joint company founder Alvin Ufibro, who founded the company with his mother. They came across Silverson while researching mixing equipment that would be able to make the company vision of high quality moisturisers into a reality.

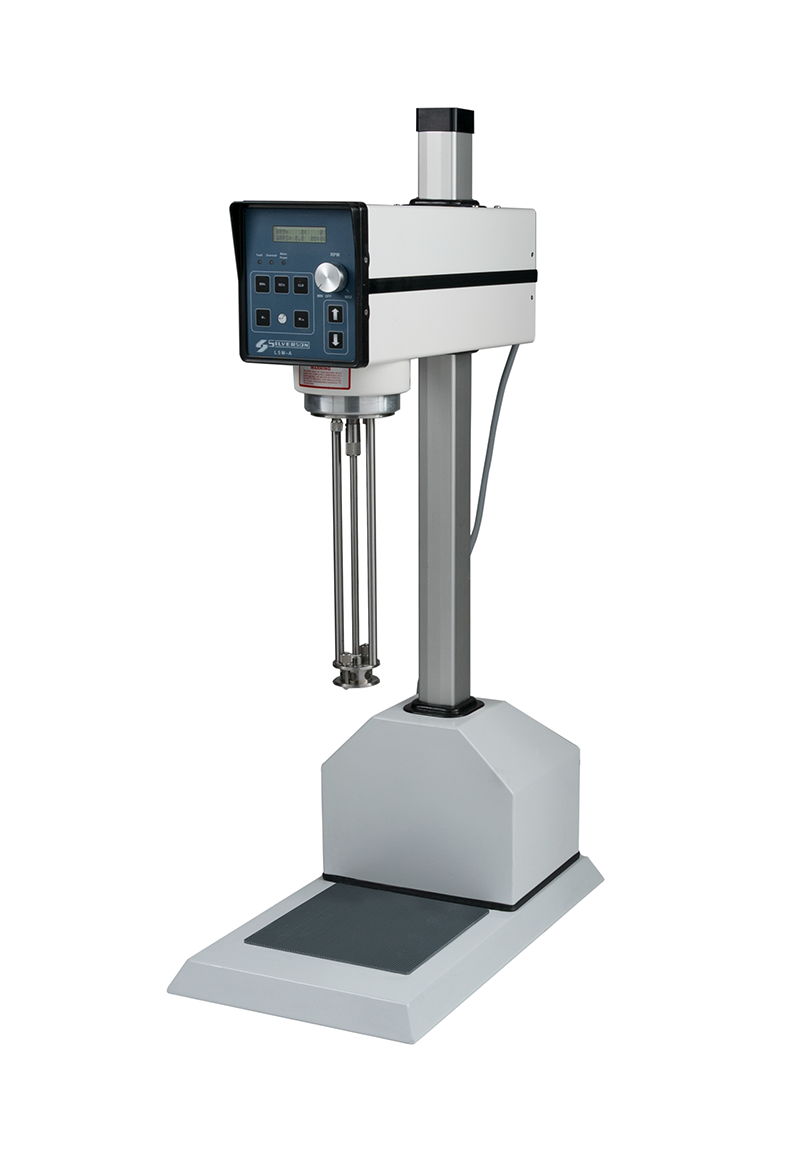

The timing of the enquiry came during the Coronovirus lockdown and as a result no trials could be performed prior to the company purchasing a mixer, but one of the reasons Alvott chose Silverson Machines was based on the company’s reputation as one of the world leaders in the field of high shear mixing and previous work with other reputable household brands. Alvott trusted the knowledge and reputation of Silverson and ordered an L5M-A Laboratory mixer. The decision paid off instantaneously with vast improvements to both product quality and process times. The laboratory mixer worked so effectively and smoothly for this application that soon after a second laboratory mixer with a Duplex assembly was purchased for manufacturing the moisturising body creams.

If you’re making a cosmetic cream or lotion, mixing is the critical stage in forming a stable emulsion and obtaining the right consistency, skinfeel and functionality in the end product. To create a stable emulsion you must obtain a fine, uniform droplet size in both the oil and water phases and this is virtually impossible to do using conventional mixing equipment such as agitators and stirrers, even with the use of an emulsifying agent, due to the low shear nature of the mixers. However, high shear equipment such as Silverson mixers are ideal for this application as they are able to impart vast amounts of shear energy into the mix. The more shear energy introduced, the smaller the droplets will become until they are completely dispersed into one another, creating a stable, homogeneous emulsion.

Using natural butters and coconut oil in their formulation and now using Silverson mixers for the process of creating the emulsion Alvott have been very happy with results. By choosing the right mixing equipment for this application they have seen improved quality and have reduced their mixing times by two thirds.

Chief of operations Alvin Ufibro says: “Our company believes in providing our customers with the absolute best quality products and we believe that it starts from the ground up. From our packaging down to the way we make our creams. That’s why we chose Silverson. By using Silverson we know we’ll be able to make and give our customers the best quality moisturisers.”

Alvott are now producing these moisturisers exclusively with their Silverson Laboratory mixers to ensure consistency and the company are planning to expand their mixing capacity to larger volumes after being approached by a well-known multinational supermarket chain specialising in high end natural products, who are interested in stocking their range. As all Silverson mixing equipment is built to the same fine tolerances, the scale-up process from Laboratory scale to Pilot scale or full scale production is an easy process and products do not need to be reformulated.

One of the unique advantages of using Silverson mixing equipment is that one mixer can be used for several different processes and applications due to the range of interchangeable workheads and Alvott are now diversifying their product range with the release of a new hand bar product for which they are using their Silverson Laboratory mixers for the initial phase. This product has been developed as an alternative for customers who do not like the greasiness of traditional hand lotions when moisturising their hands on the go. They are also using their Silverson mixers in the development stage of many other additional products such as chapsticks to achieve consistency and the same high quality for which the Alvott brand is known for.